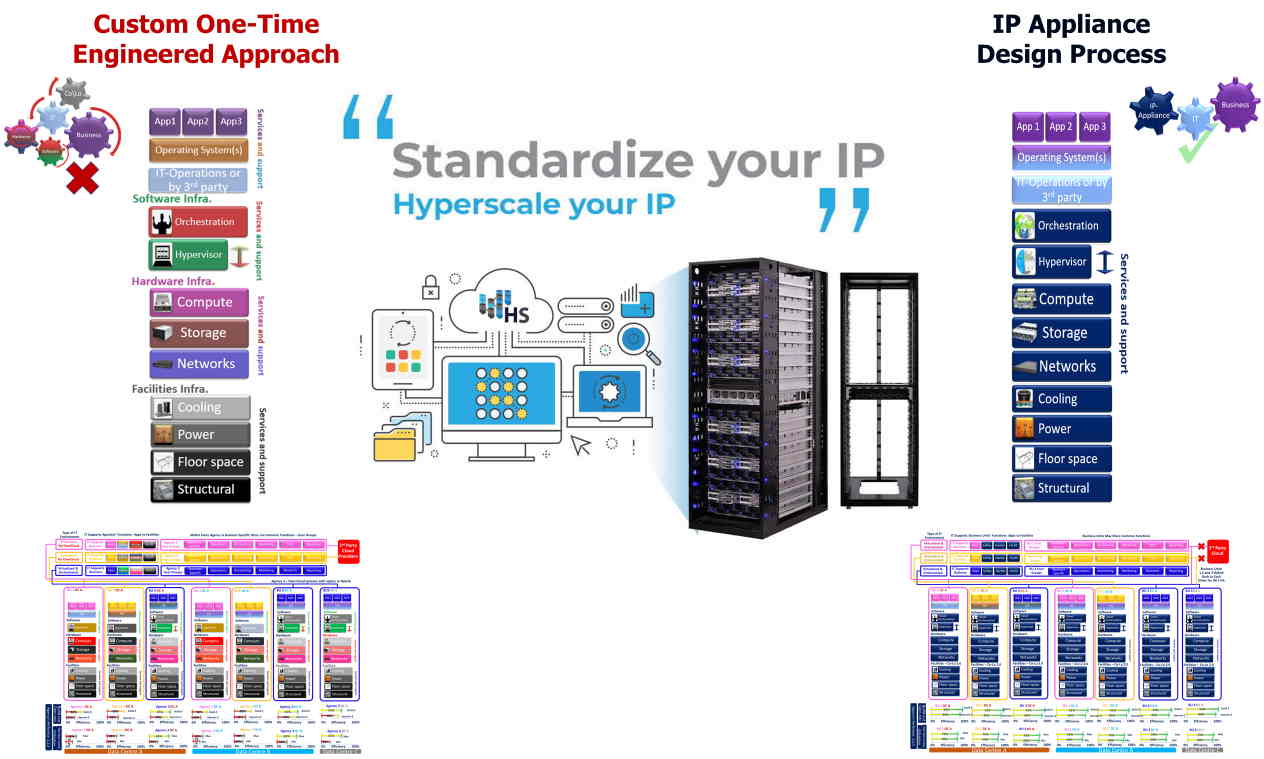

Digital IP Appliance Design Process

Hyperscalers has developed a Digital- IP-Appliance Design Process along with a utility, being the Appliance Optimizer Utility (AOU), which together accelerates the creation of appliances for use by cloud service provides, managed service providers and original equipment manufacturers needing to hyperscale their services very quickly, reliably and at a fraction of traditional cost.

Appliance Optimizer Utility AOU

The Appliance Optimizer Utility AOU automates the discovery of appliance bottlenecks by pinging all layers in the appliance stack. A live dashboard unifies all key performance characteristics to provide a head-to-head performance assessment between all data path layers in the proposed appliance and a more common appliance.

The Problems with Custom, One-Time Engineered Cloud Data Centers

The industry landscape, dominated by the competing interests of locked OEM giants, means that standardization across open supply chains and its inherent benefits can never be realized over time. Complex, custom engineered outcomes are the result. These solutions are brittle – i.e. not flexible or adaptable enough to accommodate change or extension over longer product lifespans that are relevant now.

In the absence of movement towards open supply chain standards, service providers are at risk of continuing to follow traditional OEM vendors down disparate paths of ad-hock, one-time engineered investments costing significantly more over time than an open and coordinated approach.

Data center projects fail due to:

Hardware-Lock-Ins - by proprietary OEM vendors meaning at a time of an HDD SSD or NVMe upgrade you are locked in and have nowhere else to go. This can be a problem if a contractual problem has occured, and the vendor is wanting to put pressure on you.

Software-Lock-Ins - by proprietary OEM vendors means that it's impossible to repurpose the appliance be it an expensive server or switch (and all associated sub-components/interface modules).

Non-interoperability - once infrastructure sub-systems are locked down by OEM vendors, they become non-interoperable by design. Perhaps even a version upgrade across the rest of your network fabric might become a problem.

Complexity - data center projects are already inherently complex. Proprietary lock-ins add a completely unnecessary layer to this complexity. Even when all sub-systems are operational, the one-time engineering of the whole solution may mean that it is never actually optimized. Retaining appropriately trained and skilled staff needed for optimization and operation of the various 3rd party sub-systems across the entire life-cycle is also very difficult to do.

Project: Risk Time & Cost - The IP-Appliance Design Process eliminates or at least mitigates all of the above problems & challenges in cloud data centers. The result of this process is a standardized and tested solution stack that does contain locked down elements meaning that it can be evolved further and freely as your needs dictate over time.

Contact us to Hyperscale your Services Today

Hyperscalers' 10 Core Functions:

|

|

|

|

|

|

|

|

AUS site

AUS site